IMAGIC IMS – from acquisition to reporting

ALL WITH A SINGLE SOFTWARE

Customers typically use our Image Management System - "IMS" - for the entire workflow of their optical inspection, from image acquisition, administration, measuring & annotation, analysis to documentation.

The modular design of IMS allows tailoring individual solutions for any customer requirements, from single-station systems with minimal equipment to network solutions across different sites with distributed recording and reporting stations.

Learn more about the wide range of IMS modules in the functional sections Image Acquisition, Image Management, Processing / Measuring / Annotation, Image Analysis and Documentation.

Image acquisition

ONE USER INTERFACE

FOR ALL YOUR IMAGING DEVICES AND FORMATS

With just one user interface, we support all imaging devices in your lab and read the required image formats for you.

A single user interface for the control of the complete laboratory: from Canon EOS models to various microscopes and microscope cameras; directly controlled with fully automated reading of calibration and relevant metadata.

As hardware-independent system integrator, we focus on integrating all cameras as well as encoded/motorized microscopes of our customers into IMS.

IMS reads metadata from over 180 image formats, even the relevant metadata of proprietary formats of various digital microscopes, e.g. from Keyence and Olympus DSX series, as well as formats from many electron microscopes. Please provide the image formats to be read to your Imagic representative, we have a solution for you.

Demanding samples

Optimally visualized

The sample is non-planar and contains reflections, the image does not show the complete "region of interest"? With the IMS acquisition tools, you get the best out of your sample even under most difficult conditions.

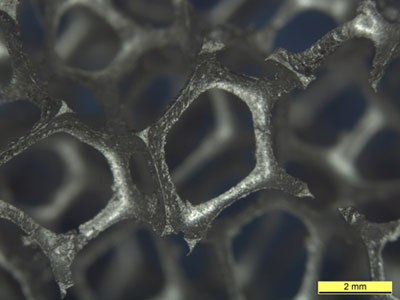

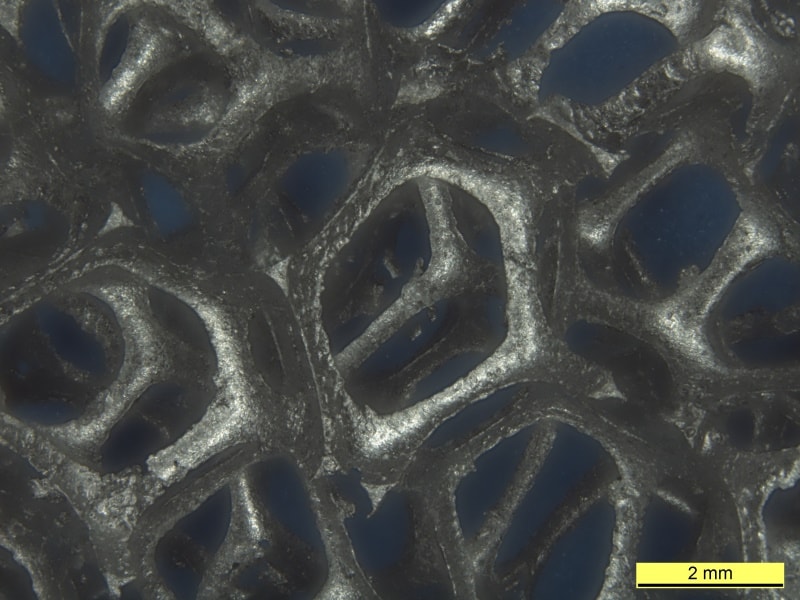

IMS module Multifocus for the compensation of a lack of depth of field

By acquisition and automatic calculation of several images of different focal planes of a sample section, a result image with high depth of field is achieved even at high magnifications.

IMS module High Dynamic Range „HDR“ for the compensation of high exposure differences

The acquisition and automatic calculation of several images with different exposures of a sample allows to achieve an optimally exposed image, even if samples with high contrast are difficult to illuminate.

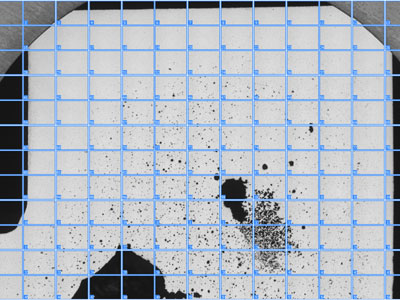

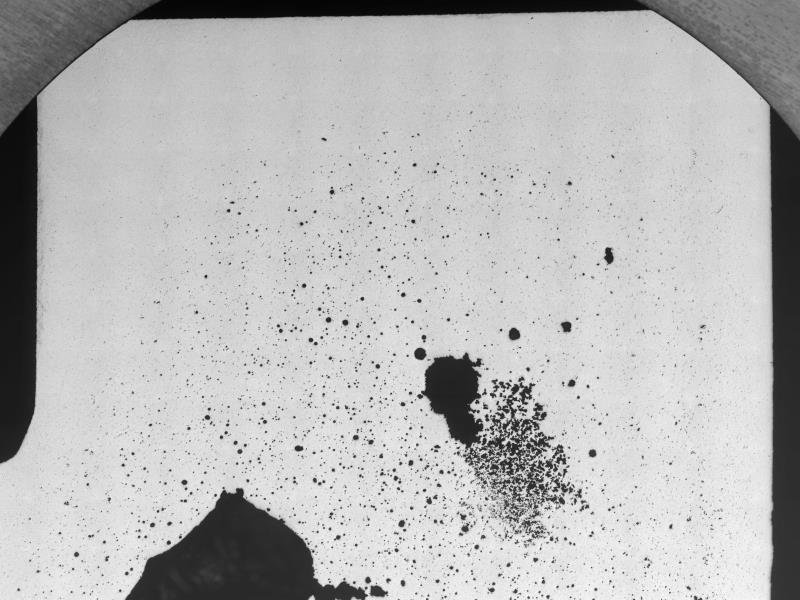

IMS module Panorama Scan for the acquisition of large samples at high resolution using XYZ scanning

With the optimal number of sub-images and automatic assembly, even for large samples you can achieve a representative overview image in the required resolution.

The acquisition modules are available as manual or automatic solution.

Image management

RELEVANT INFORMATION

QUICKLY FOUND

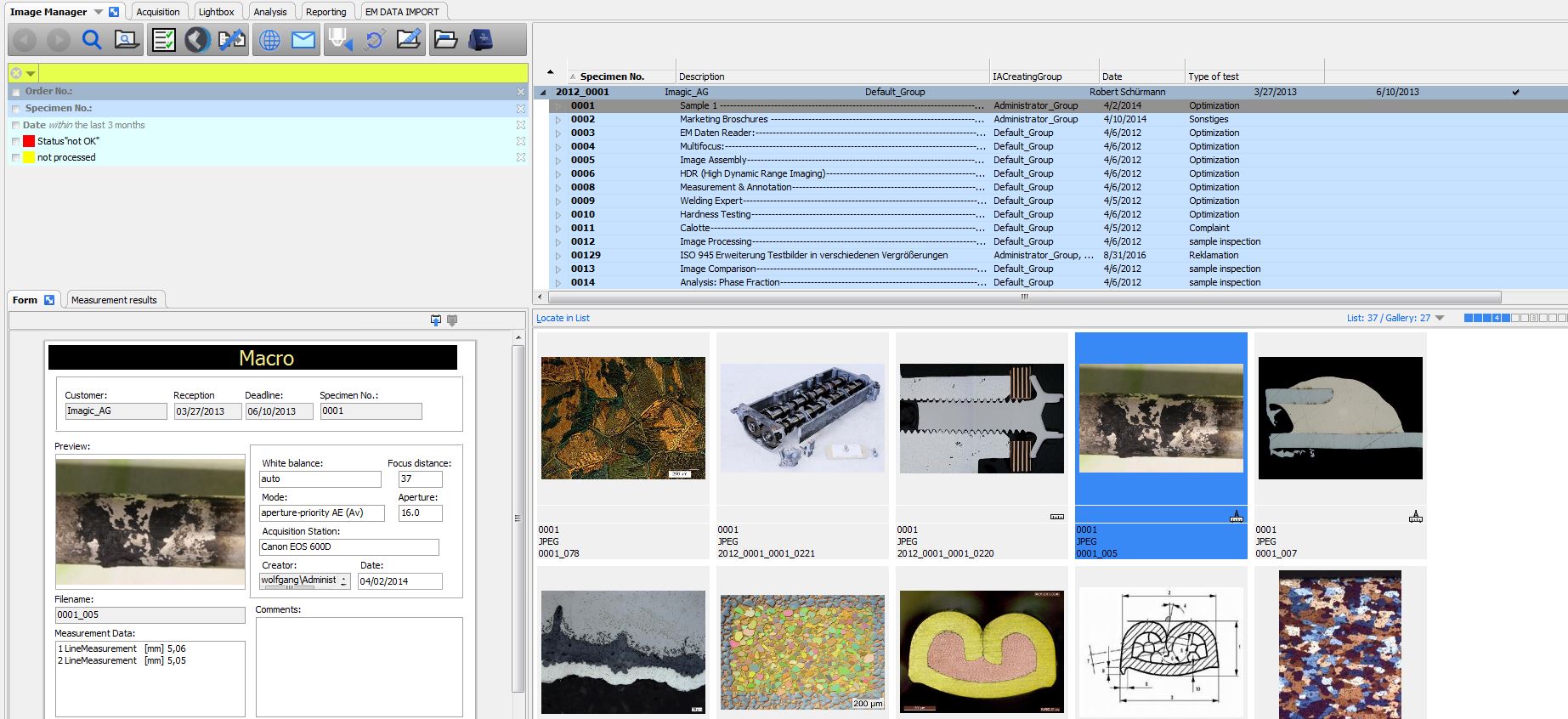

An image management system often manages hundreds of thousands of data. In order to keep the focus on the essentials despite the data volume and to always find the desired parts quickly, optimized clarity as well as efficient data filtering play a central role.

The IMS Client with the Image Manager together with the IMS Server are the heart of the IMS image database. In addition to the administration of the entire image material with metadata, any additional document types such as Word®, Excel®, PPT®, PDF can be stored in an order-oriented way.

In addition to the standard filter functions for the individual metadata fields, the IMS Client provides an optional Quick Search module.

Quick search means internet-like, instant identification and display of the desired information in the entire inventory of hundreds of thousands of hierarchical records. Just search for familiar terms, word parts, combination criteria and placeholders.

ACCESS AND EXCHANGE

WHO, wHEN, HOW: ITS YOUR DECISION

IMS provides both an XML-based and a Web-based REST interface for the data exchange with 3rd-party systems, such as laboratory or order management systems (LIMS), which can be adapted individually to customer requirements.

The flexible group and user administration can be managed directly in the IMS server or can optionally be synchronized with the customer's LDAP system.

The IMS Client Workplace allows group- and user-specific allocation of access rights to data and functions.

Processing, measurement and annotation

Saving results in image

All tools available without change of application

Even with best acquisition technology, postprocessing can often effect a significant optimization of the result image. Whether you want to adjust the depth of field, improve contrast, enhance colour, or simply rotate and cut, the IMS image processing module offers you a large number of image processing tools.

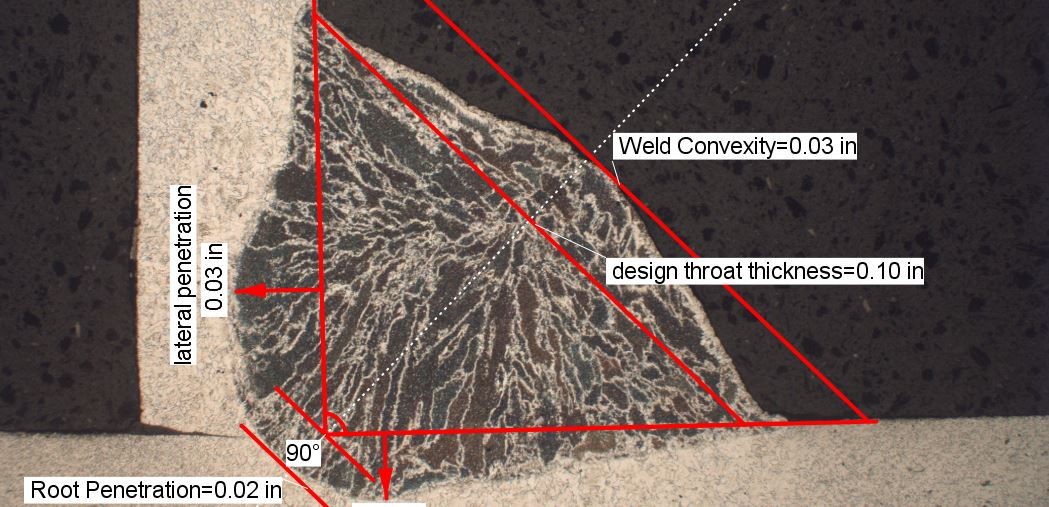

For efficient documentation of examinations, the IMS Measuring and Annotation module provides all basic functions such as distance, area, circle, angle and object counters. The following special functions are also supported:

- Live image measurement: single or serial measurements directly on the live image, with optional transfer to Excel

- Special measurements: guided measurement workflows such as for weld seam and hardness indentation

- Automated measurements: user-defined work flows with step-by-step user guidance

All measurement and annotation data can be saved as editable image overlay or can be irrevocably merged into the image.

Image analysis

Automated image analysis

to reliable results in just a few clicks

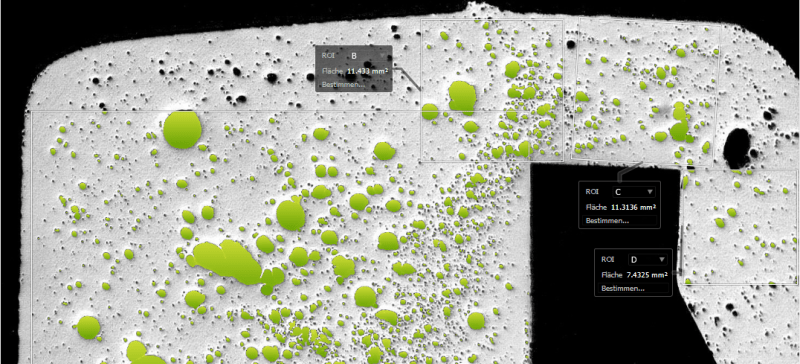

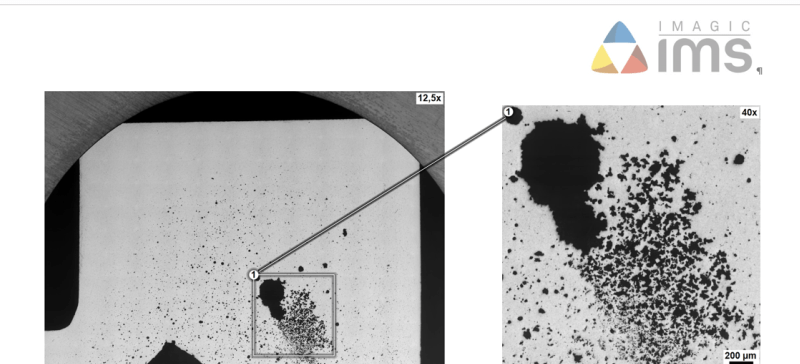

Intuitive and fast, in just 2 clicks from the image selection to the final analysis report. You can, however, intervene at any time in the process, change settings, and save analysis templates for reuse.

In addition to the internal IMS analysis modules for standard tasks, we work together with long-time partners for special analysis types.

Do you have special questions regarding the analysis of certain materials? Simply contact your Imagic representative.

Selected analysis modules:

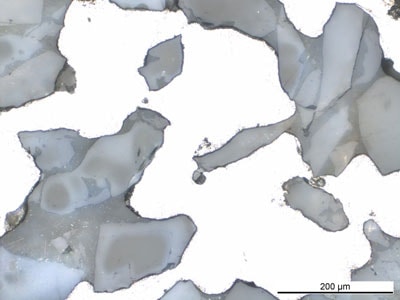

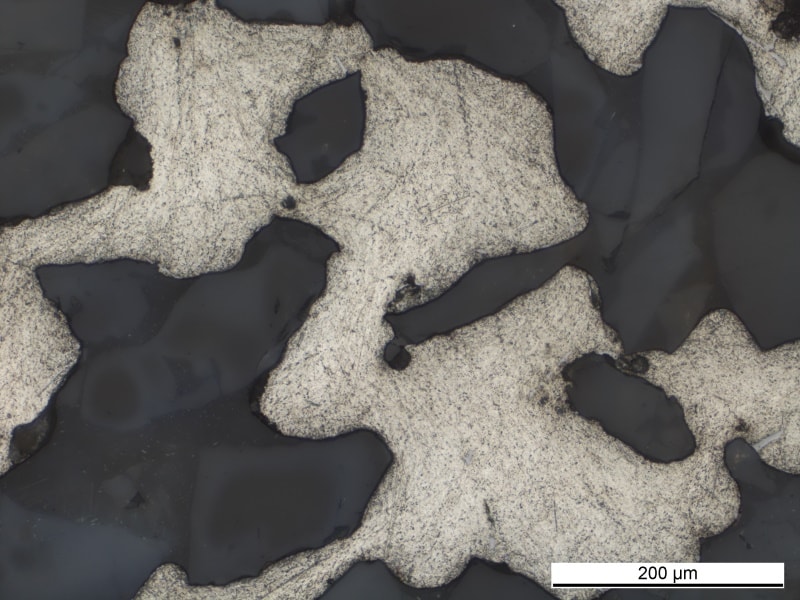

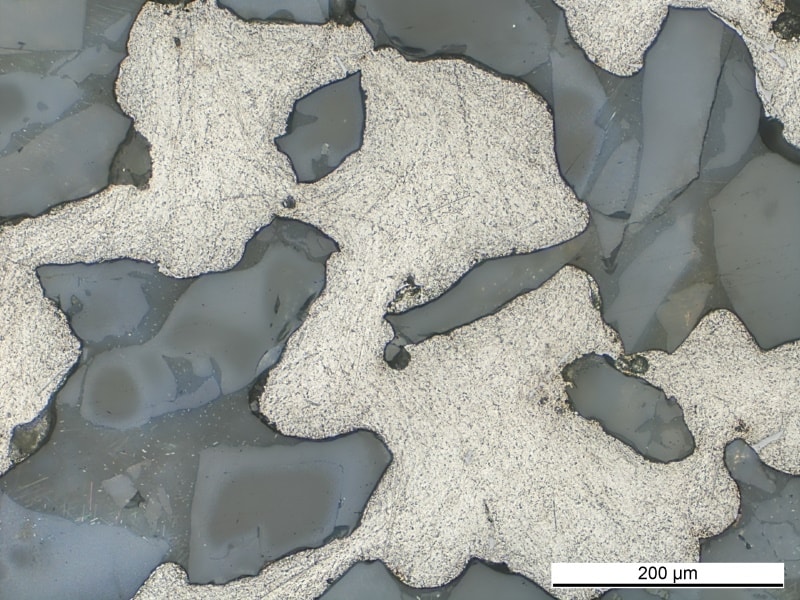

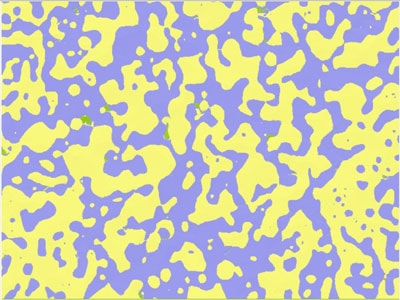

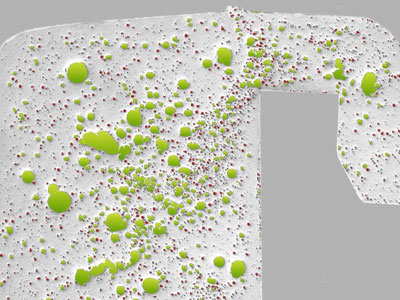

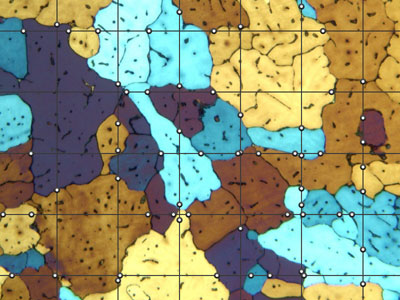

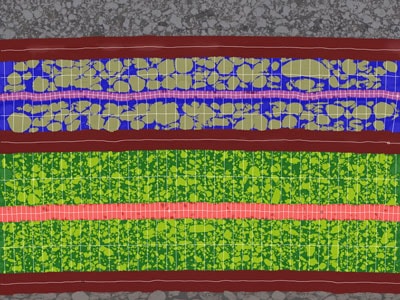

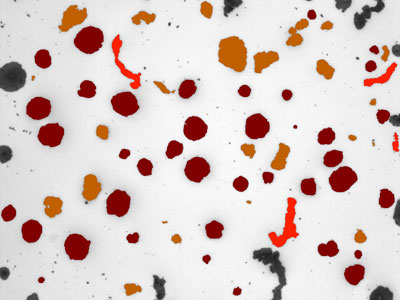

Analysis of the microstructure of graphite in cast iron according to the standard EN ISO 945.

In addition to the parameters graphite size (slat length), graphite shape and graphite order, the graphite percentage, nodularity, graphite particles absolute and per area, and the ferrite/pearlite ratio are also calculated automatically.

Documentation

Analysis results

presented individually

Test report in Word®, presentation in PowerPoint® or web-based download facility for users without IMS:

With custom templates or directly in the application, with the IMS Word® and PowerPoint® modules you work as usual in your Microsoft Office® environment. What makes the difference is our certified add-in with many extra features, allowing easy and time-saving creation of analysis reports and presentations.

Thanks to a permanent connection between Word® / PowerPoint® and the IMS database, images and measurements can be updated in reports and presentations in seconds.

With the IMS Publisher your colleagues or vendors have an easy and secure Web-based access to images and metadata without the need for an IMS workstation.