Inspection plan conform measurEment data management

Production-aligned testing results in a large amount of measurement data. This data is often collected manually and created from different sources, to be passed on to the master system (CAQ system) for the documentation of the inspection plan.

With its guided measurement process and automated Smart Data Export to Excel, Imagic IMS offers a consistent workflow, avoiding errors and saving time.

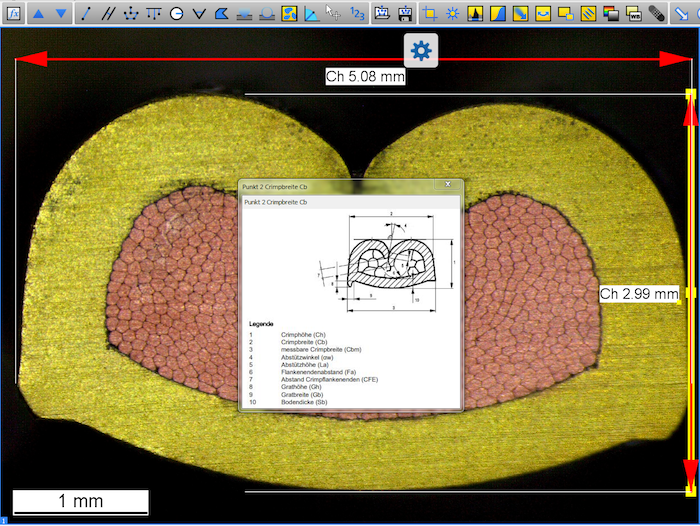

Guided measurement procedure based on the predefined inspection plan

Imagic IMS offers the possibility to define standardised measurement procedures. Users then are guided step by step through the measurement tasks. This saves training time and ensures the measurement process is completed correctly every time.

crimp with measurement procedure to be tested

Automated data export to suitable third-party application

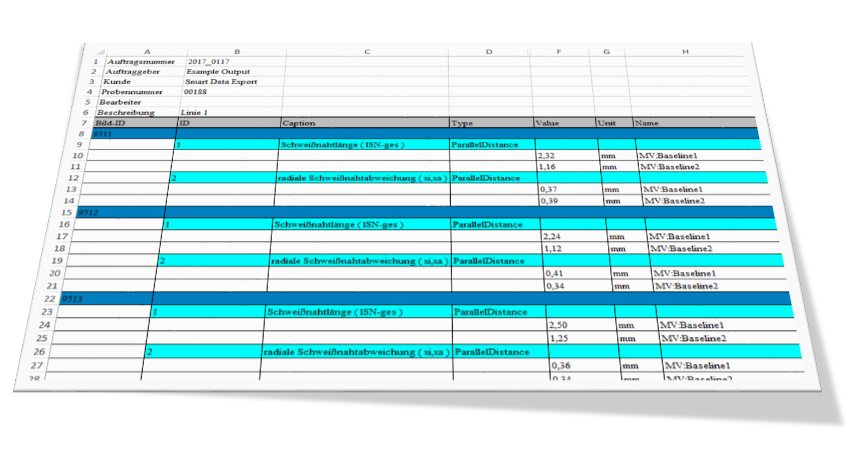

The IMS Smart Data Export enables customised export of the measured data to Excel in a single step, tailored to your test plan. The selection of data to be exported is image-oriented and based on standard IMS Client tools. The transfer interface manages multiple output layouts and is adaptable to your needs.

Figure:

sample report of a measurement series

-

Guided measurement procedure based on predefined inspection plan

-

Automated data export in an appropriate format directly to Excel

-

Substantial time saving and minimization of errors

Figure:

detail sketch of rolling bearings

In order to comprehensively record your requirements and implement them optimally, we will gladly advise you personally.